BACKGROUND

At Lumen, when customers terminate or move their services, we request the return of Wi-Fi extender pods while retaining the modem in the customer’s home, referred to as a “Smart NID.”

IDENTIFYING THE PROBLEM

A Product Manager wished to prevent customers from returning the modem (Smart NID) when returning the pods. Before initiating the project, we needed to validate the business problem. We explored scenarios, considering what would happen if customers didn’t return the Wi-Fi extenders or returned everything.

We discovered that when Lumen does not receive the Wi-Fi extenders, it incurs significant costs due to refurbishment needs. Conversely, having all equipment returned was even more expensive, as it meant removing the modem from the customer’s location. This disrupted our goal of instant internet activation for new customers, undermining our marketing strategy.

THE CHALLENGE

The challenge we faced was ensuring a streamlined return process for customers discontinuing service. How could we improve return protocols to avoid unnecessary expenses and maintain seamless service activation for new users?

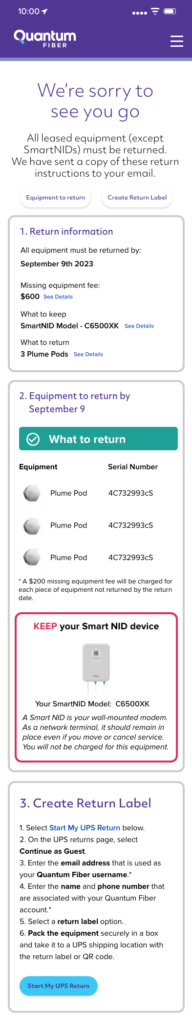

ANALYSIS OF EXISTING FUNCTIONALITY

An initial assessment of the current system revealed a message indicating a $200 fine per unreturned item, potentially causing customers to rush to return all items to avoid the penalty.

Hypothesis for Improvement

The instructions were incomplete and not sufficiently detailed.

The instructions were too verbose and confusing.

There were not enough pictures.

The pictures were not representative or helpful.

RESEARCH AND TESTING

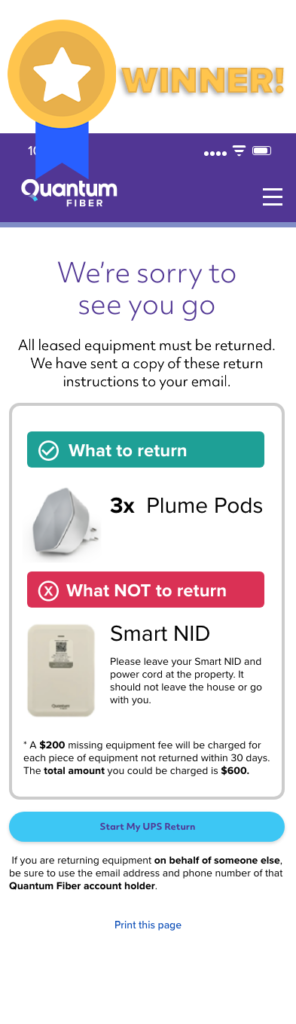

We fostered a collaborative, cross-functional team environment where various design iterations were explored. These designs aimed to address the problem from multiple angles. We formed hypotheses for improvement, considering issues such as incomplete or verbose instructions, and inadequate or unhelpful visuals. For the first round, we decided to compare three different designs: the existing system, a design with more explicit instructions, and a minimalist version emphasizing visuals over text.

Existing

Detailed Concept

Simplified Concept

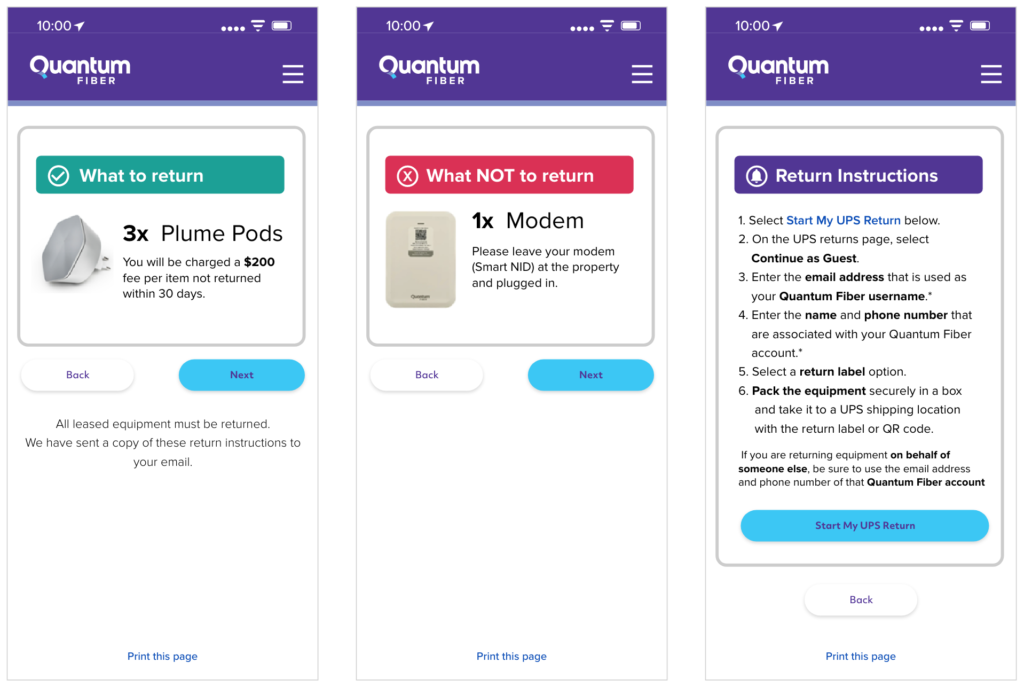

Given the urgency of the project, we adopted a lean iterative testing approach. This allowed for rapid recruitment and testing without elaborate documentation or presentations. Our approach integrated R&D seamlessly into the process, avoiding siloed deliverables and instead opting for immediate team review and decisions, fostering rapid iterative development. We conducted two testing rounds within two weeks.

TESTING RESULTS

The initial round demonstrated that a pictorial version with minimal text significantly outperformed the other designs, indicating the value of visual cues over detailed instructions. Moving to the second phase, we assessed whether presenting information on one page or multiple pages would enhance clarity. The outcome favored multiple pages with succinct content and primarily visual guidance, resulting in a 73% improvement over the initial approach.

IMPLEMENTATION AND RESULTS

Based on these findings, we projected potential return numbers and proceeded with implementing the refined design. Upon launch, data collection revealed close alignment between our projections and the actual return and incorrect return numbers.

OUTCOME

The streamlined visually-oriented design significantly improved the return process, aligning with projected outcomes and addressing the complexities associated with returning equipment, thereby optimizing operational efficiency. This focused approach ensured a more intuitive and user-friendly process for customers, minimizing unnecessary costs and maintaining our commitment to seamless service activation for new users